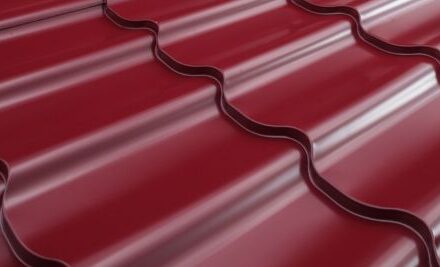

Prepainted steel offers a durable and cost-effective solution, making it a preferred choice for many manufacturing and construction companies and businesses in many industries. It offers customizable surface finish options and color combinations to provide businesses with a broad spectrum of options to cater to their specific needs. Prepainted steel is produced through a coil coating process, which provides many advantages to manufacturers across a broad range of market applications.

Applications of Prepainted Steel

Stainless steel color coating, achieved by utilizing stainless steel coils as the foundation, involves chemical treatment of the surface and the application of organic coatings. This process results in a material characterized by high corrosion resistance and strength. Such prepainted metal finds diverse applications in:

- Public Buildings: Public buildings, known for their heavy usage, can benefit from the longevity and aesthetics of prepainted metal. The material provides an attractive and durable finish.

- Airports and Stations: Prepainted metal’s durability and resistance to corrosion make it a suitable choice for construction projects at airports and transportation hubs, ensuring structures withstand the test of time.

- Stadiums: The robust nature of prepainted metal is ideal for stadiums, which face high foot traffic and exposure to the elements. It maintains its integrity, even in demanding conditions.

- Power Plants: In the demanding environment of power plants, where exposure to chemicals and extreme conditions is common, prepainted metal stands as a corrosion-resistant solution, ensuring the structural integrity of the facilities.

- Chemical Industry: The chemical industry, where corrosive substances are prevalent, benefits from the corrosion-resistant properties of prepainted metal, making it a reliable choice for equipment and structures.

- Coastal Areas: Coastal regions, characterized by high humidity and salt exposure, require materials with exceptional corrosion resistance. Prepainted metal is well-suited for such environments.

- Solar Energy: In the field of solar energy, where equipment is exposed to weather conditions, prepainted metal offers durability, ensuring the longevity of solar installations.

- Automotive: Original equipment manufacturers, OEMs, utilize prepainted metal in their manufacturing process to provide higher quality products and cost-saving efficient processes.

- Aeronautics and Aerospace: airplanes and spacecraft benefit from the high-quality, corrosion-resistant properties of prepainted metal.

Prepainted metal, with its exceptional properties, caters to a wide range of applications with high-performance requirements, making it a versatile choice in various industries.

UNICHEM: Prepainted Metal Coil Coating Solutions Provider

Coil-applied coatings are a specialized process involving the application of protective coatings to metal coils before they undergo transformation into building products. UNICHEM, Inc., a leading manufacturer of coil-applied coatings, stands at the forefront of innovation in the construction industry. Our coatings are meticulously crafted to deliver outstanding durability, weather resistance, and long-lasting color vibrancy.

At UNICHEM, we have tailored our coil-applied coatings to meet the stringent demands of the building materials sector. Our extensive range of coatings each possesses unique properties and performance characteristics. These coatings are skillfully applied using advanced techniques, ensuring uniform coverage and exceptional adhesion to the metal substrate.

Our collaborative approach with customers is at the core of achieving optimal performance in chemical and coating applications tailored to specific environmental demands. Our committed research team collaborates closely with you, focusing on asking the pertinent questions that lead to the creation of customized formulations. These formulations not only deliver superior performance but also offer exceptional value.

Our scientists possess profound expertise in various technical domains, including resin science, polymer chemistry, and adhesive technology. We continually push the boundaries of innovation, working alongside a dedicated research and development team. This dedication allows us to consistently explore new frontiers in the realm of chemical and coating solutions.

UNICHEM’s coil-applied coatings excel in providing exceptional corrosion resistance, forming a protective shield that safeguards the metal substrate from deterioration. Leveraging advanced pigment technology, our coatings exhibit superior color retention, even when subjected to harsh weather conditions. For inquiries and further insights into our coil-applied coatings, please do not hesitate to contact us.