In the last article, we covered the suitability of a chosen adhesive to meet the requirements of bonding substrates for assembly or lamination. Many manufacturing processes produce laminates of various substrates such as for building and construction products and automotive products. The industrial adhesives used for assembling laminated products is of critical importance for product quality and performance.

In the last article, we covered the suitability of a chosen adhesive to meet the requirements of bonding substrates for assembly or lamination. Many manufacturing processes produce laminates of various substrates such as for building and construction products and automotive products. The industrial adhesives used for assembling laminated products is of critical importance for product quality and performance.

The three most important steps when considering assembly with industrial adhesives include:

- Suitability

- Compatibility

- Capability

In this article, we will discuss the importance of Compatibility.

Compatibility of Industrial Adhesives for Assembly

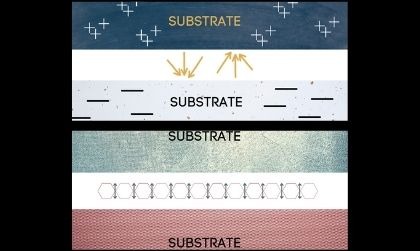

Compatibility refers to the ability of an adhesive to bond to both surfaces of an assembly, which can be the same or different materials. When assembling dissimilar materials, the surface adhesion characteristics will differ and reliable adhesion to both types of surfaces can be an issue. For example, joining a polymer to metal or adhering polystyrene to glass can be fraught with challenges if not using the right type of industrial adhesive, or if not properly preparing the surfaces.

Some common adhesives used in assembling and laminating include epoxies, urethanes and acrylics. Traditionally, epoxy adhesives have been popular when bonding metals or ceramics as well as composites, although are less commonly used for bonding polymers. Acrylic adhesives perform well on many types of materials and can be used for metals, polymers and composites, although have lower strength and temperature resistance than epoxies. Urethanes are used for bonding some metals, like aluminum, and for laminating composites to metals or to more composites, and also for bonding polymers.

Surface Preparation Helps Adhesion with Low Dyne Level Substrates

The right type of adhesive must be chosen to successfully bond with the surface of the substrate, or both substrates if bonding dissimilar materials. This can be challenging when bonding substrates with a low dyne level which typically require surface preparation to improve adhesion. Heat treating or corona laminating equipment use high-voltage electrodes to alter the surface energy of a substrate to better prepare the surface to accept adhesion.

Benefits of Using Structural Adhesives With or Without Mechanical Fasteners

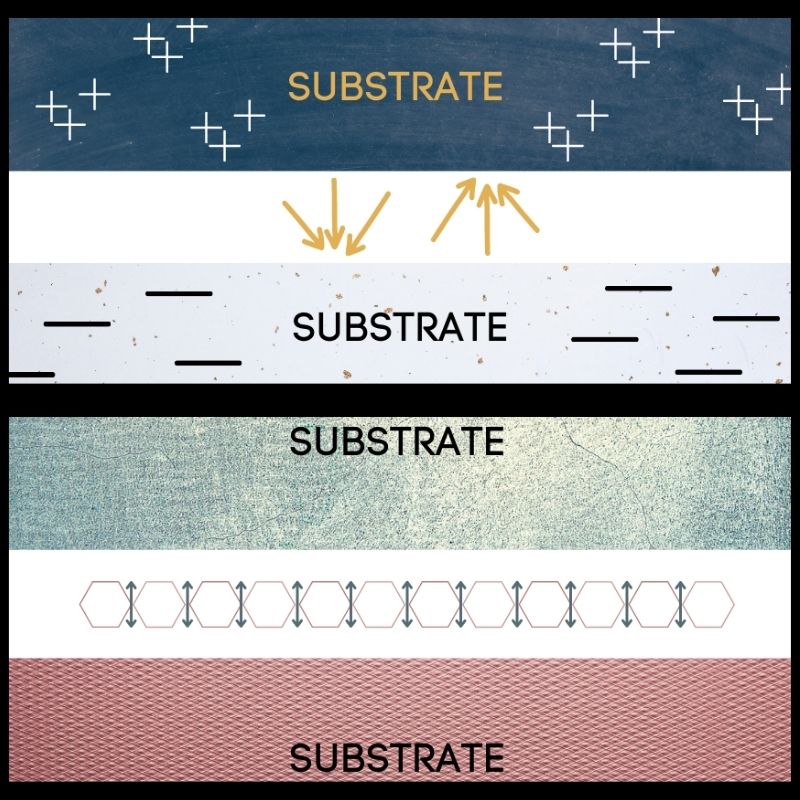

Specialty, custom formulations of adhesives help laminating applications and play a critical role when assembling challenging substrates. Customized structural adhesives provide many advantages to design engineers and manufacturers and in many cases can replace welding and mechanical fastening. There are times when mechanical fasteners are necessary such as for odd-shaped products or challenging dimensions that require a mechanical connection. When structural industrial adhesives can be used, bonded laminates experience many benefits such as:

- A more even distribution of stress

- Greater reduction of vibration and noise

- Resistance to corrosion

- Improved aesthetics

- Solutions for joining dissimilar materials

- Reliable bonding in one step

In order to experience the many benefits of reliable structural adhesives that are suitable and compatible to your application, it is critical to work with an experienced custom chemical and coating manufacturer.

uniBOND Industrial Adhesives Bond Low Dyne Substrates

Universal Chemicals & Coatings, Inc., UNICHEM, is a custom chemical and coating manufacturer with more than 50 years of experience. We offer uniBOND industrial adhesives which have been proven successful in many laminating to metal, vinyl, rubber, fiber composites, and many other types of materials. With UNICHEM, you have an adhesive expert on your team offering solutions to meet your material suitability and compatibility requirements.

UNICHEM is an industry-leading chemical and coating manufacturer with in-depth knowledge of polymer chemistry and resin science. We conduct rigorous testing and real-life simulations to ensure long-lasting adhesion performance. Contact us to learn how to improve your laminating process when bonding or assembling with industrial adhesives.