The use of adhesives dates back to Neanderthal times when birch bark tar was used to help adhere spear stones to wood. Beginning in the early 1900s, more scientific research went into industrial adhesives and how to improve stronger bonds as part of an urgency to improve aircraft for World War I. The evolvement of adhesives since then has led to a wide array of applications such as:

- Strong, biodegradable bonds used in the medical industry

- Flexible adhesives that provide vibration and sound control for the automotive industry

- Durable lamination bonding for use in aerospace and aircraft

- Industrial adhesives provide structural integrity for construction applications

With strong and flexible adhesive bonds increasing in demand, the future of industrial adhesives is only limited by our imagination. So, what are the various types of industrial adhesives and how do they work?

Different Adhesion Types

Bonding can occur from different methods that can overlap with each other. The different types of adhesion bonding include mechanical, electrostatic, and chemical processes that join parts or substrates together.

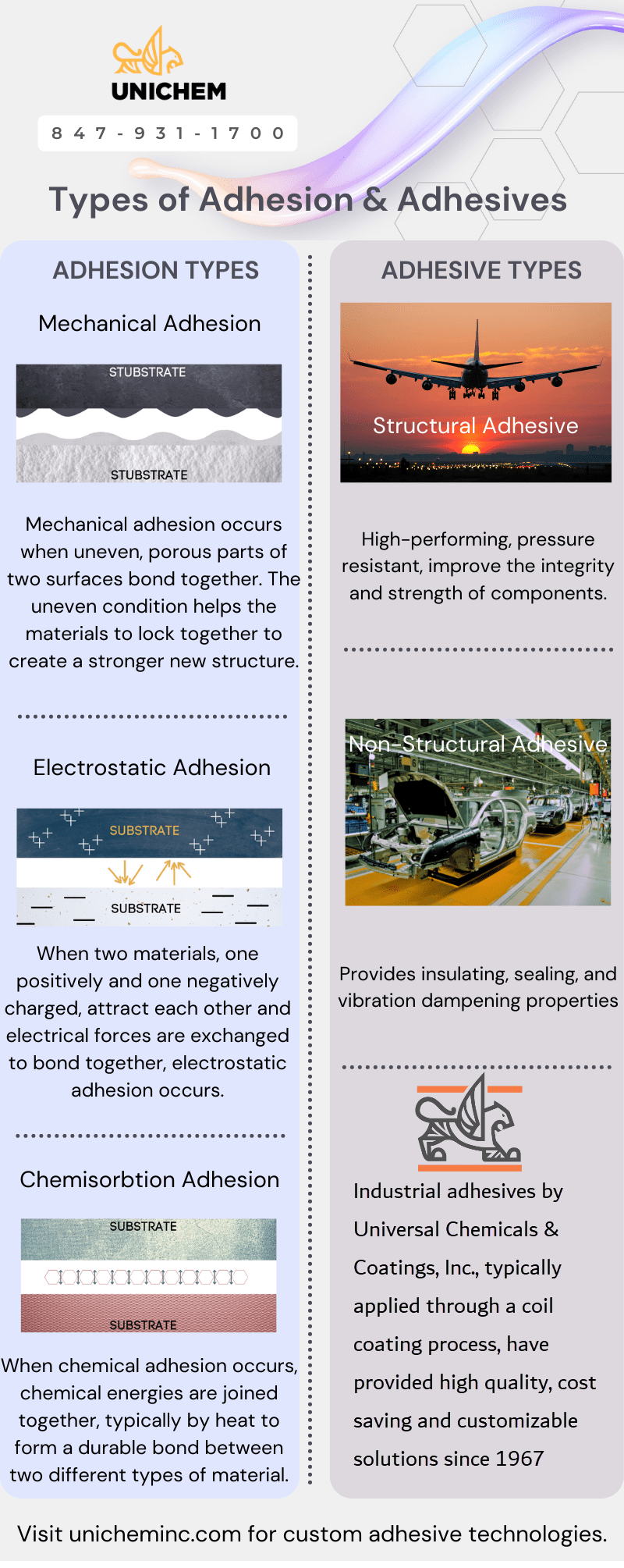

- Mechanical adhesion

- Mechanical adhesion occurs when uneven, porous parts of two surfaces bond together. The uneven condition helps the materials to lock together to create a stronger new structure.

- Electrostatic adhesion

- When two materials, one positively and one negatively charged, attract each other and electrical forces are exchanged to bond together, electrostatic adhesion occurs.

- Chemisorption adhesion

- When chemical adhesion occurs, chemical energies are joined together, typically by heat to form a durable bond between two different types of material.

Other types of adhesion occur through adsorption, which happens when two materials bond on a molecular level. Diffusion is an adhesion type that occurs when particles blend together to form an adhesive bond.

Types of Adhesives

There are different types of adhesives such as structural, nonstructural, pressure sensitive, solvent-based and water-based adhesives.

Structural adhesives

Structural adhesives are designed to be high-performing, pressure resistant and to improve the integrity and strength of components. Structural adhesives are designed to provide the product service life aligned with the application in which they are used. Different types of structural adhesives include polyurethanes and epoxies.

Nonstructural adhesives

Nonstructural adhesives are typically used more like short-term fasteners and may degrade quicker over time then some heavier duty structural adhesives. Nonstructural adhesives may be designed to hold light to moderate weight loads with a lower chemical and temperature resistance to exposure. Nonstructural adhesives can provide insulating, sealing, and vibration dampening properties.

Pressure sensitive adhesives

Pressure sensitive adhesives firmly adhere to various types of surfaces without additional pressure required to provide a permanent bond. Pressure sensitive adhesives can be solvent-based such as elastomers. Water-based adhesives have lower toxicity although may also have low resistance to moisture.

Hot melt adhesives

These types of hot melt adhesives provide tolerance and high-performance under high temperatures due to thermoplastic properties.

Industrial Adhesive Specialists Provide Troubleshooting and Support

When you want to know the best type of adhesive for your application, contact an experienced industrial adhesive expert such as Universal Chemicals & Coatings, Inc., UNICHEM. UNICHEM has been an industry leader in custom adhesive and coating manufacturing for more than 50 years, offering uniBOND industrial adhesives. uniBOND industrial adhesive product line includes:

- uniBOND Fiber Composite Adhesive

- uniBOND L VINYL Adhesive

- uniBOND Polyethylene and Polypropylene Adhesives

- uniBOND PVC Adhesive

- uniBOND Rubber Adhesive

- uniBOND TPO Adhesive

Our industrial adhesive experts provide troubleshooting and ongoing support including custom chemical manufacturing to meet your application needs.

UNICHEM is a leading Midwest custom chemical and coatings provider, offering high-quality industrial adhesives, coatings, and paints. We employ the leading, high-tech resin and coating specialists in the industry, with vast product and market expertise. Contact us to learn how to improve your industrial adhesive application with uniBOND industrial adhesive and customized solutions.