In the fast-paced world of manufacturing, precision and quality are paramount. Whether you’re producing delicate electronic components, sophisticated machinery, or high-end appliances, maintaining the integrity of your products is essential. This is where protective films step in, playing a crucial role in safeguarding the surfaces of manufactured goods during various stages of production and transportation.

The Role of Protective Strippable Films

Protective strippable films are versatile solutions designed to shield surfaces from scratches, abrasions, dirt, and other potential damage. They provide an invisible yet robust barrier that preserves the aesthetics and functionality of the manufactured items.

Benefits of Protective Films in Manufacturing

- Surface Protection: The primary function of protective films is to safeguard the surface finish of products. Whether it’s polished metal, high-gloss plastics, or sensitive screens, these films prevent damage during handling, assembly, and transportation.

- Quality Assurance: By preventing scratches, stains, and scuffs, protective films ensure that the finished products meet quality standards and maintain their brand-new appearance.

- Cost Savings: Utilizing protective films can lead to significant cost savings by reducing the need for costly rework or refinishing of damaged surfaces.

- Ease of Removal: These films are designed to be easy to remove without leaving residue, ensuring that the end product is ready for use or sale without further processing.

- Customization: Protective films can be tailored to fit various surfaces and requirements, providing flexibility in manufacturing processes.

UNICHEM’s uniGUARD Temporary Protective Strippable Films

When it comes to reliable temporary protective strippable films, UNICHEM is a trusted name in the industry. UNICHEM’s uniGUARD temporary protective strippable films are engineered to provide optimal protection for manufactured goods, from delicate components to high-end finishes.

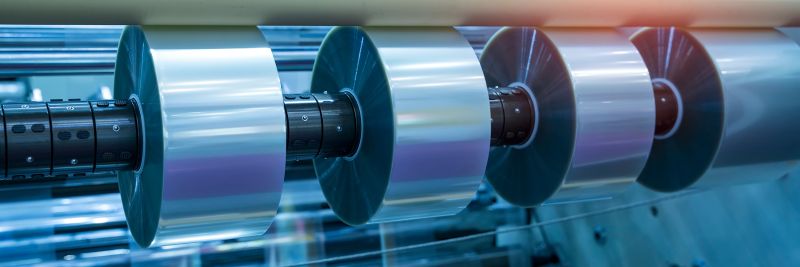

Our versatile range of solvent-borne and water-based liquid strippable coatings are applied similarly to adhesives and standard coatings on a coil processing line. Liquid strippable formulations create a robust barrier that resists abrasion, moisture, and chemicals. The flexibility and rigidity of these coatings can be tailored to specific applications, offering a wide range of performance options. Whether you need a soft and pliable or hard and durable solution, these coatings can be customized to meet your requirements.

Typically, liquid strippable coatings are applied as a second stage, following the application of the primary finish coating. This often occurs on entire coils before they are slit into specific widths. Alternatively, these coatings can be sprayed onto pre-cut sheets or finished parts. In cases where precision protection is needed, such as appliance control panels, screen-printing techniques can be used.

Once applied, these coatings solidify into protective films during heating and processing. Their versatility extends to adhesion options, allowing them to be used on various substrates, from polished metals to plastics and even other coatings. Adhesion levels can be adjusted to suit specific requirements for forming and stamping operations. Once solidified, these coatings provide protection during post-processing operations like die-cutting and bending without causing surface damage.

In the construction industry, durable liquid strippable coatings prove invaluable for protecting finish coatings on building products, including siding and roofing, even polyvinylidene difluoride (PVDF) coatings. This protection guards against scratches and damage during shipping and handling. In the automotive sector, these coatings shield vehicle surfaces during transportation. For this application, coatings are formulated to be sprayed at thicknesses ranging from 3 to 4 mils, providing ample protection from debris kicked up by trucks and other vehicles on the road.

Increasingly, liquid strippable coatings are becoming a preferred alternative to film laminates in applications such as kitchen appliances and construction products, encompassing siding, roofing, garage doors, and roof and wall panels, offering enhanced value and protection. uniGUARD ensures that your products emerge from the manufacturing process in pristine condition. UNICHEM’s temporary protective strippable films offer peace of mind, knowing that your investments are protected from start to finish.

When you need dependable temporary protective strippable films, consider UNICHEM. Protective films are indispensable tools in the manufacturing industry, helping preserve the quality and value of products. Contact us to learn more about our uniGUARD temporary removable strippable films.