Whether you are creating new products or improving existing ones, the team and Universal Chemicals and Coatings is here to help. Our coil applied coating and adhesive chemistries have a wide range of applications and can also be adapted to meet new demands. Contact UNICHEM early on in your planning and development process to ensure the chemistry meets your specific requirements and provides the best quality and value as a key element of your products.

Understanding Coil Coating and Adhesives

This section of our site has been created in order to help you both understand the coil process, learn the advantages (and yes, sometimes limitations), and consider how our adhesives and coatings can work for you. We will draw your attention to the more informational pages on the site so that you can understand the usages and applications and try to keep back from a lot of the highly technical information provided throughout the rest of the site.

Applications and Solutions for Products Across Many Industries

Prepainted metal and coil applied adhesives can be used for a vast array of products for use in a large number of industries including:

It can be quite easy to talk about the things our chemistries have already been user for – but our engineers and chemists are always looking forward to creating custom solutions for products and applications that have never been done before. In general terms, our line of products can be used for the following broad purposes (just to name a few)…

General Features of Coatings

- Longevity: Prepainted Metals in products are more resistant to chipping and peeling, making your product last longer.

- Rust/Corrosion Resistance

- Antimicrobial Protection

General Features of Adhesives

- Adhesion across Media: Using a bucket of glue to connect some materials to metal just won’t cut it. UNICHEM has solutions to connect metal to Vinyl, PVC, Polyethylene and Polypropylene, TPO (Thermoplastic Olefin), and many more.

Information and Case Studies

Our blog is an amazing resource for learning more about our chemistries and the applicable industries and products. We also have a growing collection of Case Studies and real world usage scenarios for inspiration and guidance.

Coil Applied Coatings

Why Color Consistency Defines Quality in Doors and Windows

Consistency in operations is the key to quality. For door and window manufacturers, maintaining consistent aesthetics…

More… Why Color Consistency Defines Quality in Doors and Windows

Designing for Durability: How Abrasion-Resistant Coatings Improve Lifecycle Performance of Steel Products

Why Abrasion Resistance Matters for Steel Components Steel products are built for strength, but their long-term…

See More About…

Industrial Adhesives

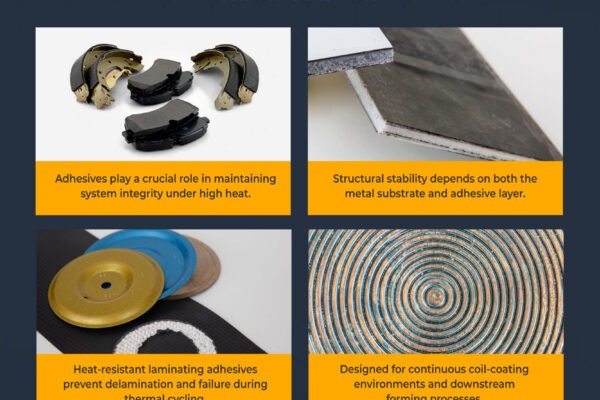

The Science of Heat-Resistant Laminating Adhesives-Infographic

Steel and aluminum components in appliances, HVAC systems, and automotive assemblies face extreme temperature fluctuations every…

More… The Science of Heat-Resistant Laminating Adhesives-Infographic

Ensuring Long-Term Bond Integrity Under Heat

Manufacturers in the appliance, HVAC, and industrial markets depend on laminated materials that must withstand constant…

See More About…

Case Studies

Case Study – Custom Coil-Applied Epoxy Coatings for Decorative Metal Components

OVERVIEW A leading manufacturer of decorative metal components faced significant challenges sourcing custom coil-applied coatings for…

More… Case Study – Custom Coil-Applied Epoxy Coatings for Decorative Metal Components

Case Study – First-to-Market Innovative Drum Lining Developed for Coil Coating Application

OVERVIEW: Drum manufacturers and chemical packagers rely on drum linings for storing and transporting bulk quantities…

More… Case Study – First-to-Market Innovative Drum Lining Developed for Coil Coating Application

See All of our Case Studies