Thermo-setting Adhesive

UNICHEM offers thermosetting adhesive solutions for coil applied lamination processes. Thermosetting adhesives are renowned for their strong, durable bonds and efficiency in coil in-line laminations, and manufacturing operations with B-stage curing requirements.

Showing all 6 results

-

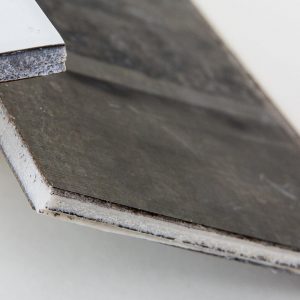

uniBOND Fiber Composite Adhesive

uniBOND Fiber Composite Adhesives – this type of adhesive uses a single or two-stage process. Both applications are initially applied by coil coating and cured. During the second “B” stage heating process, the adhesive is activated to permanently bond a composite assembly. B stage adhesives are used in many stamping operations and automotive processes such as for brake shoes, clutch pads and gasket materials.

uniBOND Fiber Composite Adhesive by Universal Chemicals and Coatings, Inc., UNICHEM, delivers high-performance and cost effective solutions when industrial adhesives are applied with coil coating as the application method.

Available in single stage (uniBond-FC-100) and two stage (uniBond-FC-200) curing formulations.

-

uniBOND L VINYL Adhesive

Vinyl laminate adhesives by Universal Chemicals & Coatings, Inc., UNICHEM, provide exceptional performance with added value to many coil coating, laminating vinyl to metal applications.

Available in single stage (uniBond-VINYL-100) and two stage (uniBond-VINYL-200) curing formulations.

-

uniBOND Polyethylene and Polypropylene Adhesives

uniBOND Polyethylene or Polypropylene Adhesives – these adhesives, by UNICHEM, are suitable for bonding polyethylene or polypropylene films and insulative cores to a variety of substrates including various types and grades of aluminum, electrolytic tinplate and steel substrates. Typical applications are wherever composite panels and walls are needed, such as in transportation, tractor trailers, building products, consumer goods and many other markets.

Polyethylene Adhesive available in single stage (uniBond-PE-100) and two stage (uniBond-PE-200) curing formulations.

Polypropylene Adhesive available in single stage (uniBond-PP-100) and two stage (uniBond-PP-200) curing formulations. -

uniBOND PVC Adhesive

uniBOND PVC Adhesives – complements UNICHEM’s roofing adhesive offerings by providing a robust single or two stage adhesive providing excellent long term performance over the full range of ambient service temperatures and installation conditions.

uniBOND PVC Adhesive, like many of UNICHEM’s other roofing membrane adhesives offers the end user wider operating windows of application and bonds strong enough to assure membrane failure, meeting the stringent demands of the roofing industry.

Available in single stage (uniBond-PVC-100) and two stage (uniBond-PVC-200) curing formulations.

-

uniBOND Rubber Adhesive

uniBOND Rubber Adhesives – These adhesives provide excellent laminating bonding for a variety of rubber type compounds to metal substrates such as steel and aluminum. There are many end applications in the general industrial markets such as noise dampening, vibration reducing as well as thermal or electrical insulation panel applications.

-

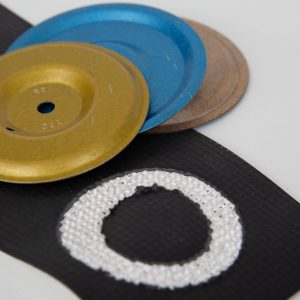

uniBOND TPO Adhesive

uniBOND TPO Adhesives – uniBOND TPO Adhesives, by UNICHEM is commonly applied by coil coating process and laminates and membranes can be laminated on line to create a bond stronger than the TPO itself. TPO is one of the fastest growing commercial roofing installation products in the market. Whether you need a single or two stage system, UNICHEM’s uniBOND TPO adhesives provide improved strength and durability for PE or PP based TPO materials which can be further customized to meet your needs.

uniBOND TPO Adhesive was developed for the commercial roofing industry with innovative technology and provides reliable adhesion of single-ply membranes with coil coated metal roofing pucks.

Available in single stage (uniBond-TPO-100) and two stage (uniBond-TPO-200) curing formulations.

Thermosetting Adhesives

Unlike thermoplastics, thermosetting adhesives do not melt or soften with heat once cured. Instead, they undergo a chemical transformation that creates permanent, heat-resistant networks between the adhesive and the substrate. This chemical curing process involves cross-linking, where the polymer chains form strong bonds that set into a fixed position, effectively making the adhesive insoluble and infusible.

Thermoset adhesives are a significant component to various industrial applications, particularly in environments that demand high durability and resistance to temperatures and chemicals. The irreversible curing process provides a durable, permanent bond and when combined with B-stage curing processes, adds a layer of flexibility to support efficient manufacturing.

Key Properties of Thermosetting Adhesives

Thermosetting adhesives are renowned for their exceptional performance in demanding environments, characterized by their superior heat resistance, chemical stability, and mechanical strength. These adhesives can withstand prolonged exposure to high temperatures without losing their structural integrity, making them ideal for applications where other adhesives might fail. Additionally, their chemical stability ensures resistance against solvents, oils, and other harsh chemicals, further extending their usability across various industries.

Among the types of thermosetting adhesives, acrylic thermosetting adhesives are notable for their excellent adhesion and durability, making them suitable for both automotive and construction applications where environmental resistance is critical.

Industrial thermoset adhesives, including epoxy and phenolic-based formulas, offer robust solutions for automotive and heavy machinery due to their high thermal stability and strong bonding capabilities. Each type brings specific advantages to the table, catering to distinct requirements and applications, ensuring optimal performance under stress.

Advantages of Thermosetting Adhesives in Coil Coating

Using thermosetting adhesives in coil coating processes through B-stage curing, presents several benefits. This method involves applying the adhesive in a partially cured state to one side of the coil while the other side receives a protective coating. The adhesive is not fully cured initially, but is tack free, allowing the coil to be rolled, transported, and stored in a dry and tack-free state. When the coil is later unrolled for final application, the adhesive is reactivated by heating, becomes tacky, providing a permanent bond effectively with a second substrate under pressure.

This B-stage processing enhances the durability of the adhesive bond and increases the efficiency of the production line. It allows for a controlled curing process, which is essential for maintaining consistent quality and performance. Additionally, the ability to cure the adhesive only at the point of final assembly reduces waste and energy consumption, contributing to cost-effectiveness. The reliability and performance of thermosetting adhesives in coil coating lines make them particularly valuable in high-demand industrial applications, where long-lasting, robust adhesive solutions are crucial.

Industry Applications of Thermosetting Adhesives in Coil Applied Adhesive Applications

Automotive and Transportation

In the transportation sector, thermosetting adhesives are extensively utilized due to their superior resistance to high temperatures and harsh chemicals. These properties make them ideal for use in various panel laminations where materials must withstand rigorous conditions without degradation. The durability and chemical resistance of thermosetting adhesives help in extending the lifespan of automotive components, contributing to vehicle safety and reliability.

Construction Elements

Thermosetting adhesives play a critical role in the construction industry, particularly in applications requiring robust adhesive solutions that can endure environmental stresses and provide long-lasting bonds. They are in coil coating processes to bond panels and other construction materials that must resist weathering, thermal cycling, and mechanical loads. Thermosetting adhesives help to ensure structural integrity and durability in building components, essential for modern construction practices.

Appliances & HVAC

In the appliances and HVAC markets, thermosetting adhesives are crucial for manufacturing equipment where strong, durable bonds are required to withstand varying temperatures and operational stresses. These adhesives are used in the manufacturing of various appliances and HVAC units where adhesive stability and performance under thermal stress are paramount. The ability of thermosetting adhesives to maintain their properties over time ensures the reliability and efficiency of appliances and HVAC systems.

These applications highlight the versatility and essential nature of thermosetting adhesives in providing high-performance adhesive solutions across diverse industries.

Choose UNICHEM for Coil Applied Thermosetting Adhesives; In-Line or B-Stage

UNICHEM is renowned for our deep expertise and unwavering commitment to innovation in the development of specialized thermosetting adhesives. By focusing on advanced research and embracing cutting-edge technologies, UNICHEM ensures that our adhesive products meet the highest standards of performance and quality. Our dedication to engineering custom solutions is evident in our ability to adapt formulations to specific industrial needs, ensuring that every adhesive application is optimized for both functionality and durability.

We understand that each client has unique requirements, which is why we offer extensive support and customization options. Whether you need a thermosetting adhesive that withstands extreme temperatures or one that offers exceptional chemical resistance, UNICHEM works closely with you to develop a solution that perfectly matches your specifications. Our technical team is committed to providing comprehensive support throughout the product selection and application process, ensuring a seamless integration into your coil applied adhesive production line.

UNICHEM offers more than 50 years of experience as a leading custom coating and chemical manufacturer, offering coil applied adhesive and coating solutions. Let UNICHEM help you find the perfect adhesive solution customized to your needs. Contact us today to speak with an adhesive expert and learn more about improving your coil applied lamination process with superior thermosetting adhesives.