Chemical Resistant Adhesive

A chemical resistant adhesive is a specialized type of bonding material designed to withstand exposure to harsh chemicals and environmental conditions.

What is a Chemical Resistant Adhesive?

Chemically resistant adhesives are formulated to maintain their integrity and bonding properties when subjected to solvents, oils, acids, and other industrial chemicals. This makes them essential for applications where materials are prone to chemical attack, which can degrade ordinary adhesives, leading to failure in structural integrity and functionality. The use of chemical resistant adhesives is crucial in industries such as chemical processing, pharmaceuticals, automotive, and aerospace, where durability and safety are paramount.

Showing all 6 results

-

uniBOND Fiber Composite Adhesive

uniBOND Fiber Composite Adhesives – this type of adhesive uses a single or two-stage process. Both applications are initially applied by coil coating and cured. During the second “B” stage heating process, the adhesive is activated to permanently bond a composite assembly. B stage adhesives are used in many stamping operations and automotive processes such as for brake shoes, clutch pads and gasket materials.

uniBOND Fiber Composite Adhesive by Universal Chemicals and Coatings, Inc., UNICHEM, delivers high-performance and cost effective solutions when industrial adhesives are applied with coil coating as the application method.

Available in single stage (uniBond-FC-100) and two stage (uniBond-FC-200) curing formulations.

-

uniBOND L VINYL Adhesive

Vinyl laminate adhesives by Universal Chemicals & Coatings, Inc., UNICHEM, provide exceptional performance with added value to many coil coating, laminating vinyl to metal applications.

Available in single stage (uniBond-VINYL-100) and two stage (uniBond-VINYL-200) curing formulations.

-

uniBOND Polyethylene and Polypropylene Adhesives

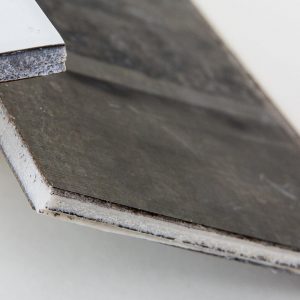

uniBOND Polyethylene or Polypropylene Adhesives – these adhesives, by UNICHEM, are suitable for bonding polyethylene or polypropylene films and insulative cores to a variety of substrates including various types and grades of aluminum, electrolytic tinplate and steel substrates. Typical applications are wherever composite panels and walls are needed, such as in transportation, tractor trailers, building products, consumer goods and many other markets.

Polyethylene Adhesive available in single stage (uniBond-PE-100) and two stage (uniBond-PE-200) curing formulations.

Polypropylene Adhesive available in single stage (uniBond-PP-100) and two stage (uniBond-PP-200) curing formulations. -

uniBOND PVC Adhesive

uniBOND PVC Adhesives – complements UNICHEM’s roofing adhesive offerings by providing a robust single or two stage adhesive providing excellent long term performance over the full range of ambient service temperatures and installation conditions.

uniBOND PVC Adhesive, like many of UNICHEM’s other roofing membrane adhesives offers the end user wider operating windows of application and bonds strong enough to assure membrane failure, meeting the stringent demands of the roofing industry.

Available in single stage (uniBond-PVC-100) and two stage (uniBond-PVC-200) curing formulations.

-

uniBOND Rubber Adhesive

uniBOND Rubber Adhesives – These adhesives provide excellent laminating bonding for a variety of rubber type compounds to metal substrates such as steel and aluminum. There are many end applications in the general industrial markets such as noise dampening, vibration reducing as well as thermal or electrical insulation panel applications.

-

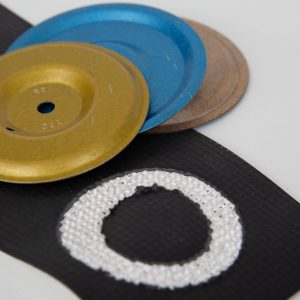

uniBOND TPO Adhesive

uniBOND TPO Adhesives – uniBOND TPO Adhesives, by UNICHEM is commonly applied by coil coating process and laminates and membranes can be laminated on line to create a bond stronger than the TPO itself. TPO is one of the fastest growing commercial roofing installation products in the market. Whether you need a single or two stage system, UNICHEM’s uniBOND TPO adhesives provide improved strength and durability for PE or PP based TPO materials which can be further customized to meet your needs.

uniBOND TPO Adhesive was developed for the commercial roofing industry with innovative technology and provides reliable adhesion of single-ply membranes with coil coated metal roofing pucks.

Available in single stage (uniBond-TPO-100) and two stage (uniBond-TPO-200) curing formulations.

UNICHEM’s Commitment to Advanced Adhesive Solutions

At UNICHEM, we are dedicated to pushing the boundaries of adhesive technology to meet the ever-evolving needs of modern industries. Our commitment to innovation is reflected in our extensive range of chemical resistant laminating adhesives and coatings, designed to provide reliable solutions for challenging environments. UNICHEM’s industrial laminating adhesives are not only tailored to resist chemical degradation but are also developed to offer enhanced performance characteristics that meet specific application requirements. With UNICHEM, industries can achieve optimal results, ensuring longevity and efficiency in their operations.

Types of Chemical Resistant Adhesives

Chemical Resistant Epoxy Adhesive

Epoxy laminating adhesives are renowned for their exceptional strength and chemical resistance, making them ideal for use in environments where exposure to harsh chemicals is a common challenge. These adhesives are composed of polymer structures that provide a robust, durable bond, capable of withstanding aggressive chemical agents such as acids, alkalis, and solvents. Chemical resistant epoxy adhesives are frequently used in the automotive and aerospace industries for bonding components that must endure rigorous operating conditions. They are also essential in the construction of chemical processing equipment and in marine applications where resistance to water and salt spray is critical.

Acrylic Adhesive Chemical Resistance

Acrylic laminating adhesives offer a unique combination of flexibility and chemical resistance, which makes them suitable for a wide range of applications. These adhesives are particularly effective against environmental factors and can withstand prolonged exposure to UV light and moisture, which often accompanies chemical exposure. Acrylic adhesives are versatile and can be used on a variety of substrates, including metals, plastics, and composites, making them ideal for industries such as signage, laminated automotive structural components, and consumer electronics housings, where they contribute to the longevity and reliability of the products.

Applications of Chemical Resistant Adhesives

Versatile Industrial Applications

Chemical resistant laminating adhesives are integral to several critical industries, offering durability and reliability where it matters most. Their ability to maintain bond integrity in the face of harsh chemical environments makes them indispensable across a variety of sectors.

Automotive Industry

In the automotive sector, chemical-resistant adhesives are used to assemble components that must endure exposure to fuels, oils, and other corrosive fluids. These laminating adhesives via coil processes, are used to bond metal to other metals, gasketing materials, rubber or foam insulation materials used in insulation, and sound dampening components. The laminated materials are then formed into under-hood components, fuel systems housing, transmissions, battery casings, etc., where our customers construct components that ensure that vehicles remain safe and operational under all conditions. Their application helps in reducing vehicle weight to improve fuel efficiency, and may also be used to dampen sound and reduce vibration.

Construction Industry

In construction, UNICHEM’s laminating adhesives are applied via coil coating processes, and utilized to manufacture coil-applied metal-to-metal, or metal-to-membrane laminates. These composite sandwich materials. These laminated components are later used to form wall, garage door, entry door, or roof panel assemblies. These adhesives provide a permanent, durable bond that is essential for the longevity and safety of buildings and are designed to resist harsh temperature variations, and salt environments in coastal areas, which are common in residential and commercial settings.

Enhancing Product Performance and Longevity

The use of chemical-resistant, coil-applied, laminating adhesives, significantly enhances the performance and longevity of products across these industries. By providing a reliable bond that resists degradation over time, these adhesives help maintain the integrity and functionality of critical components, thereby extending the usable life of the products and reducing the need for maintenance and replacements. This reliability is crucial not only for safety and performance but also for reducing the overall cost impact throughout the product’s lifecycle.

Benefits of Using UNICHEM’s Chemical Resistant Adhesives

Enhanced Durability and Resistance to Harsh Chemicals

UNICHEM’s chemical-resistant, coil-applied, laminating adhesives are specifically engineered to offer superior durability and withstand prolonged exposure to a wide range of harsh chemicals. These adhesives maintain their integrity and bonding capabilities even under severe chemical assault, which can rapidly degrade lesser-quality adhesives. This resistance is crucial in environments like chemical processing plants or outdoor applications where materials are regularly exposed to temperature variations, and corrosive agents. The robust nature of these adhesives ensures that they do not break down or weaken, thereby preserving the structural integrity of bonded components over an extended period.

Improved Safety and Reliability in Critical Applications

The reliability of UNICHEM’s coil-applied, laminating adhesives, is paramount in applications where longevity is critical. In industries where failure of a single component can have serious consequences, the consistent performance of chemical, temperature, and corrosion-resistant adhesives, provides peace of mind. By forming strong, durable bonds that are capable of withstanding extreme conditions without degradation, these adhesives minimize the risk of failure and enhance the longevity of the materials they are used in. This reliability is backed by rigorous testing and quality control processes to ensure that every batch of adhesive meets stringent performance criteria.

Cost-effectiveness by Reducing Maintenance and Replacement Needs

Utilizing UNICHEM’s coil-applied, laminating adhesives can lead to significant cost savings over the lifespan of a product. The durability and long-lasting nature of these adhesives reduce the need for frequent maintenance and replacements that are typically associated with less resistant bonding solutions and laminate failures. For industries looking to minimize maintenance costs and field failures, choosing UNICHEM’s coil-applied, laminating adhesives can extend the life of the building materials they are used to manufacture, reducing material failures and the potential need for replacement. This cost-effectiveness is a crucial factor for businesses aiming to optimize their operational budgets and enhance efficiency.

By incorporating UNICHEM’s coil applied, laminating adhesives, companies not only ensure the longevity and reliability of their products but also benefit from the improved safety and cost savings that these high-quality adhesives provide.

Why Choose UNICHEM?

Expertise and Innovation in Adhesive Formulation

UNICHEM adhesive specialists offer a deep expertise and innovative approach to developing coil-applied, laminating adhesives, from Our state-of-the-art research labs and facilities, which are equipped with advanced product development and analytical testing capabilities. This enables us to create high-performance laminating adhesives that meet real-world challenges. Our commitment to innovation is demonstrated through ongoing research and the use of our experiences, to try to replicate actual, end use conditions, allowing us to preemptively address potential issues before they impact our clients.

Adherence to Industry Standards and Environmental Safety

UNICHEM is dedicated to maintaining the highest standards of quality and environmental safety. Our operations have been continuously ISO9001 certified for over 25 years, with the current ISO9001:2015 standard emphasizing our commitment to quality. This certification combined with our proprietary quality standards, reflect our systematic approach to meeting and exceeding customer expectations through regular operational audits and feedback sessions, which help us fine-tune our products and processes. UNICHEM laminating adhesives are designed to be environmentally safe, aligning with today’s global push towards sustainability and responsible manufacturing practices.

Customization and Client Support

At UNICHEM, we understand that each client has unique needs and challenges. We pride ourselves on offering extensive support and customization options that allow our clients to achieve optimal results with our coil-applied laminating adhesives. Whether modifying the chemical resistance, viscosity, or cure time of our adhesives, we work closely with you to develop a product that precisely meets your specifications. Our team provides ongoing support from the initial consultation through to the final implementation, on the coil line, ensuring that every client receives a tailored solution that not only meets but exceeds their performance expectations.

Looking for a Customized Chemical Resistant Adhesive?

Speak to a Specialist

Choose UNICHEM for a partnership with a leader in coil-applied, laminating adhesive technology, dedicated to quality, safety, and innovation. Discover how our expertise in adhesives and coatings can significantly enhance the durability and efficiency of your projects. Contact us today to take the first step towards upgrading your adhesive solutions with chemical-resistant adhesives.