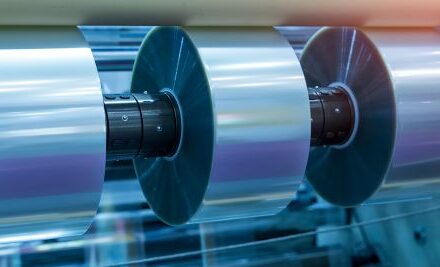

Strippable Protective Coatings Add Value to Many Industries- Infographic

Removable protective coatings are widely used across various industries to safeguard surfaces before, during, and after production. These coatings serve multiple purposes, such as masking …