Heat Resistant Adhesive

A coil-applied, laminating heat resistant adhesive is specifically formulated to maintain its integrity and bonding properties under high-temperature conditions.

What is a Heat Resistant Adhesive?

Coil applied, laminating, heat resistant adhesives are essential for applications where materials are exposed to heat during processing or operation, such as in manufacturing processes, engine parts, and electronic devices. The ability to resist thermal degradation while maintaining strength and flexibility under stress is crucial for the safety and longevity of products in industries like automotive, aerospace, and electronics, where laminations are utilized for various structural components.

Showing all 6 results

-

uniBOND Fiber Composite Adhesive

uniBOND Fiber Composite Adhesives – this type of adhesive uses a single or two-stage process. Both applications are initially applied by coil coating and cured. During the second “B” stage heating process, the adhesive is activated to permanently bond a composite assembly. B stage adhesives are used in many stamping operations and automotive processes such as for brake shoes, clutch pads and gasket materials.

uniBOND Fiber Composite Adhesive by Universal Chemicals and Coatings, Inc., UNICHEM, delivers high-performance and cost effective solutions when industrial adhesives are applied with coil coating as the application method.

Available in single stage (uniBond-FC-100) and two stage (uniBond-FC-200) curing formulations.

-

uniBOND L VINYL Adhesive

Vinyl laminate adhesives by Universal Chemicals & Coatings, Inc., UNICHEM, provide exceptional performance with added value to many coil coating, laminating vinyl to metal applications.

Available in single stage (uniBond-VINYL-100) and two stage (uniBond-VINYL-200) curing formulations.

-

uniBOND Polyethylene and Polypropylene Adhesives

uniBOND Polyethylene or Polypropylene Adhesives – these adhesives, by UNICHEM, are suitable for bonding polyethylene or polypropylene films and insulative cores to a variety of substrates including various types and grades of aluminum, electrolytic tinplate and steel substrates. Typical applications are wherever composite panels and walls are needed, such as in transportation, tractor trailers, building products, consumer goods and many other markets.

Polyethylene Adhesive available in single stage (uniBond-PE-100) and two stage (uniBond-PE-200) curing formulations.

Polypropylene Adhesive available in single stage (uniBond-PP-100) and two stage (uniBond-PP-200) curing formulations. -

uniBOND PVC Adhesive

uniBOND PVC Adhesives – complements UNICHEM’s roofing adhesive offerings by providing a robust single or two stage adhesive providing excellent long term performance over the full range of ambient service temperatures and installation conditions.

uniBOND PVC Adhesive, like many of UNICHEM’s other roofing membrane adhesives offers the end user wider operating windows of application and bonds strong enough to assure membrane failure, meeting the stringent demands of the roofing industry.

Available in single stage (uniBond-PVC-100) and two stage (uniBond-PVC-200) curing formulations.

-

uniBOND Rubber Adhesive

uniBOND Rubber Adhesives – These adhesives provide excellent laminating bonding for a variety of rubber type compounds to metal substrates such as steel and aluminum. There are many end applications in the general industrial markets such as noise dampening, vibration reducing as well as thermal or electrical insulation panel applications.

-

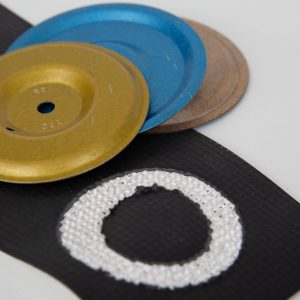

uniBOND TPO Adhesive

uniBOND TPO Adhesives – uniBOND TPO Adhesives, by UNICHEM is commonly applied by coil coating process and laminates and membranes can be laminated on line to create a bond stronger than the TPO itself. TPO is one of the fastest growing commercial roofing installation products in the market. Whether you need a single or two stage system, UNICHEM’s uniBOND TPO adhesives provide improved strength and durability for PE or PP based TPO materials which can be further customized to meet your needs.

uniBOND TPO Adhesive was developed for the commercial roofing industry with innovative technology and provides reliable adhesion of single-ply membranes with coil coated metal roofing pucks.

Available in single stage (uniBond-TPO-100) and two stage (uniBond-TPO-200) curing formulations.

UNICHEM’s (uniBOND(R)) High-Quality Heat Resistant Solutions

At UNICHEM, we specialize in developing and providing high-quality coil-applied, laminating, heat resistant adhesives that meet the rigorous demands of modern industries. Our products are designed to offer superior thermal stability and performance, ensuring that they can withstand extreme temperatures without losing efficacy. UNICHEM’s commitment to innovation and quality makes us a trusted partner in delivering adhesives that not only perform under pressure but also enhance the overall reliability and durability of the components they bond.

Types of Heat Resistant Adhesives

Heat Resistant Epoxy Adhesive

Epoxy laminating adhesives are renowned for their high thermal stability and excellent mechanical properties, making them ideal for applications requiring durable bonds that must endure high temperatures. Epoxy adhesive heat resistance is formulated to maintain its structural integrity and bonding capabilities at temperatures that would typically degrade other adhesives.

These properties make heat resistant epoxy adhesives perfect for use in the aerospace industry for assembling parts that face extreme heat during flight, in the automotive industry for engine components, and in electronics for components that generate significant heat during operation.

High Heat Resistant Adhesive

For environments that experience extremely high temperatures, specially formulated high heat resistant adhesives are required. These adhesives are designed to withstand high temperatures and rapid temperature fluctuations without losing their bonding properties or degrading. The formulations typically include ingredients that enhance thermal resistance and structural stability.

This type of adhesive is critical in industrial applications such as furnace housing manufacturing, high-temperature processing equipment, and other applications where materials are subjected to intense heat for prolonged periods.

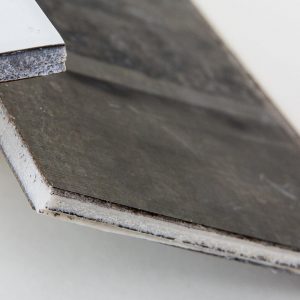

Heat Resistant Adhesive for Metal

Metal substrates pose unique challenges when exposed to high temperatures, primarily due to their expansion and contraction, which can weaken bonds. Heat-resistant adhesives for laminated metal components are specifically engineered to address these challenges, providing a secure and durable bond that can withstand the thermal expansion typically seen in metals.

Applications of Heat Resistant Adhesives

Diverse Industry Use

Heat resistant adhesives play a pivotal role across multiple sectors, ensuring the durability and functionality of components subjected to high temperatures. Their ability to maintain integrity under extreme conditions makes them indispensable in industries that demand reliability and safety.

Automotive Industry

In the automotive sector, heat resistant adhesives are essential for creating a variety of laminates used in the automotive industry. Durable, coil-coated laminate panels improve the longevity of automotive components exposed to high temperatures.

Demonstrating Effectiveness

The effectiveness of heat resistant adhesives is demonstrated through their ability to enhance the lifespan and performance of products across these industries. For instance, in the automotive industry, vehicles that utilize these adhesives require less frequent maintenance on heat-exposed parts, directly translating to cost savings and improved vehicle reliability for consumers. In aerospace, these adhesives contribute to the longevity and safety of aircraft, which are critical for mission success and operational efficiency.

Benefits of Using UNICHEM’s Heat Resistant Adhesives

Enhanced Durability and Performance

UNICHEM’s heat resistant adhesives are designed to withstand extreme temperatures without compromising their structural integrity or performance. This enhanced durability ensures that components bonded with our adhesives perform optimally even under severe heat stress, essential for applications in aerospace and automotive industries where reliability under high temperatures is crucial.

Improved Safety and Reliability

The reliability of UNICHEM’s adhesives in high-heat applications significantly improves the safety of the products they are used in. By maintaining their adhesive properties at high temperatures, these adhesives prevent failures that could lead to safety hazards, particularly in critical applications such as automotive braking systems or aerospace structural components.

Cost-effectiveness

Using UNICHEM’s heat resistant adhesives reduces the need for frequent maintenance and replacement of components exposed to high temperatures, thereby reducing operational costs. This durability extends the lifespan of the components, minimizing downtime and the associated costs of repairs and replacements, which is particularly valuable in high-stakes industries like electronics and construction.

Why Choose UNICHEM?

Expertise and Innovation

UNICHEM is a leader in the field of adhesive technologies, known for our innovative approach to developing heat resistant adhesives. Our extensive experience and state-of-the-art research facilities enable us to create advanced adhesive solutions that meet the challenging demands of modern industries, ensuring high performance even under extreme conditions.

Commitment to Quality and Environmental Safety

UNICHEM is committed to upholding the highest standards of quality and environmental safety in all our products. We adhere to rigorous industry standards to ensure that our adhesives not only meet but exceed the requirements of our clients. Our products are designed with an eye towards sustainability, minimizing environmental impact while maintaining superior performance.

Customization Options

Recognizing that each industry has unique needs, UNICHEM offers customized adhesive solutions tailored to specific requirements. Whether you need adhesives that can withstand slightly elevated temperatures or extreme heat fluctuations, we work closely with our clients to develop products that address their specific challenges effectively and efficiently.

Choosing UNICHEM means opting for a partner who understands the critical importance of heat resistance in adhesives and who can deliver products that stand up to the test, enhancing both the safety and efficiency of your operations. Contact us to learn more about our industrial adhesive solutions, including heat resistant adhesives.