Description

uniBOND Fiber Composite Adhesives

UNICHEM’s uniBOND Fiber Composite Adhesives provide many advantages with reliable and durable adhesion in a single or two-stage application process. Single stage adhesives are applied by coil coating and cured. It can then be designed to respond to a second process of heat activation in the field or during final application.

UNICHEM has been a market leader since 1967 in providing coating, adhesive and bonding solutions customized to your needs, working with you in addressing your biggest challenges. Whether you use one of our standard offerings or need us to custom engineer a specialty coating or adhesive solution, our goal is to assist you to improve your products and processes, adding value to your supply chain and your customer offerings.

uniBOND Fiber Composite B-Stage Adhesives Applications

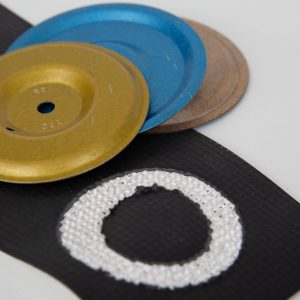

uniBOND Fiber Composite B-stage adhesives improve final assembly and serviceability of parts and assemblies requiring this type of adhesive technology in a wide variety of industries and markets. These adhesives are used in many stamping operations, heavy manufacturing gasket applications and automotive adhesive processes for brake shoes, clutch pads and a variety of gasket materials.

These high-quality, high-performance, two-stage adhesives offer wider latitude of cure response and tighter bonding which means more cost efficiencies, lower scrap rate and better value for you and your customer.

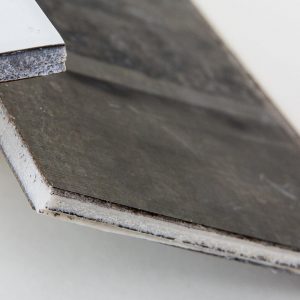

Our uniBOND Fiber Composite B-stage adhesive improves these applications with little to no edge flaking, stronger chemical resistance and wider operating windows. This delivers more reliable, long-term, consistent performance and compliance with demanding industry standards in a cost efficient manner. B-stage adhesives are a critical component in many industries as they offer a unique way to adhere material surfaces without the need to be concerned with application and curing of a liquid adhesive.

uniBOND Fiber Composite B-Stage Adhesive Advantages

uniBOND Fiber Composite B-stage adhesives provide numerous advantages to industries, applications and end users alike. Products manufactured with a two-stage adhesive process realize many benefits such as:

- Process assembly solutions – products can be coated with B stage adhesive with the final cure and adhesion of products activated at a later date

- Facility locations – the B-stage adhesive is first applied and cured then shipped to a second location for easier final assembly and permanent bonding

- Improves manufacturing cycle times – eliminate bottlenecks in production assembly lines with ready to cure products without adhesive application

Value-added service – UNICHEM’s uniBOND Fiber Composite B-stage adhesive offers a more tack free surface prior to the second stage activation, little to no edge flaking for defect-free assembly, tight edge bonding for higher quality performance and a wider operating window for reduced scrap rates and higher cost efficiency

UNICHEM’s uniBOND Fiber Composite B-stage adhesives deliver on all these advantages and more with our commitment to quality, exceptional service and flexibility to adapt to your unique needs and expectations. We have long adopted a strict quality policy as part of our ISO9001:2015 certification, beginning with our original certification in 1996 along with all of our proprietary quality assurance protocols we have operated under since our inception.

Custom Fiber Composite Adhesives Solutions

The UNICHEM team consists of the leading, high-tech scientists and engineers of the industry with deep technical knowledge of resin science and adhesive technology. You can have confidence in our more than 50 years of pursuing new frontiers in paints, coatings and adhesives with innovation and imagination.

Our multi-plant research laboratories and manufacturing facilities allow us to simulate real-world challenges with flexibility to address modern concerns providing you with the product technology you need with the service and reliability you deserve. Learn how the UNICHEM difference redefines the possibilities in your market with our interdisciplinary problem solving approach founded on resin science, adhesive technology and a commitment to quality. Our scientists and engineers partner with you to understand your expectations and develop solutions based on in-depth market and technology specializations.

UNICHEM is a leading chemical and coatings supplier, with more than 50 years of experience exceeding customer expectations with high-quality coatings and adhesives. We are dedicated to addressing your pain points with imagination, innovation and operational expertise. Contact us to learn more about our vast product line, custom engineered solutions and high-performance fiber composite adhesives.