Maximizing Thermal Bond Integrity in Coil-Applied Laminates

High-heat environments demand adhesive performance that holds up under pressure. From coil-coated HVAC panels to insulated transportation components, each product requires a bond that can endure elevated temperatures without compromising formability or longevity. Heat-resistant laminating adhesives offer that reliability, combining thermal stability with efficient in-line processing for continuous manufacturing lines.

Why Heat-Resistant Laminating Adhesives Matter

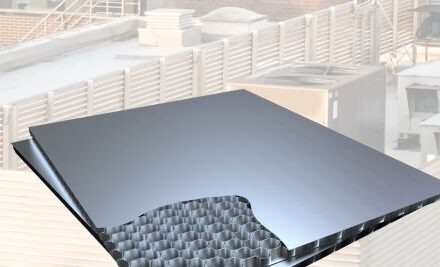

Laminating adhesives used in coil-applied systems must maintain performance under thermal cycling, forming processes, and exposure to environmental stressors. Repeated heating and cooling can weaken adhesive bonds over time, particularly when metals expand and contract during service. Heat-resistant laminating adhesives are designed to support dimensional stability and mechanical integrity through these cycles. This performance is essential in industries where components are expected to endure high service temperatures, moisture, and physical impact without bond failure.

Compared to pressure-sensitive or thermo-plastic, hot-melt options, coil-applied adhesive systems offer more permanent, stronger adhesion and better durability in thermal applications. Their use in coil-applied systems also supports efficient manufacturing, with formulations designed to cure during continuous processing, maintain uniformity across the substrate, and integrate seamlessly with line speeds and forming equipment.

Coil-applied adhesive systems deliver exceptional thermal durability and enhanced bond strength compared to surface-applied adhesives, thanks to the precision and consistency of the coil coating process. During continuous coating, the substrate undergoes thorough cleaning, pretreatment, and uniform adhesive application, producing tightly bonded, cross-linked finishes that withstand thermal cycling, mechanical stress, and environmental exposure. This controlled process creates a more reliable bond across the entire coil strip, contributing to long-term performance and aesthetic retention. Learn more about the long-lasting performance of prepainted metal.

Processing Flexibility with B-Stage Systems

For applications requiring the adhesive to be applied at one location and secondary substrate lamination at another location, UNICHEM offers B-stage curing adhesives to provide added versatility. These materials are partially cured during the initial coil coating application step, and complete their cross-linking during a secondary, lamination process, where the adhesive is reactivated, and then laminated to the second metal or membrane substrate. This approach enables flexibility in raw material management, allowing greater design flexibility while maintaining reliable adhesion in the finished product.

Coil coating lines benefit from this two-stage approach by reducing production bottlenecks and accommodating more complex geometries without sacrificing performance. B-stage systems are frequently used when components must be formed or assembled after adhesive application but still require the strength of a fully cured bond.

Industry Applications That Demand Heat-Resistant Bonding

Heat-resistant laminating adhesives play a vital role in several manufacturing sectors. These systems help ensure lasting adhesion in components that experience thermal, mechanical, or environmental stress during use:

- HVAC and Appliances: Panels exposed to high service temperatures during operation, such as in water heating systems or heating units, rely on adhesives that can maintain bond integrity over time.

- Transportation: Exterior panels, insulated containers, and mobile structures face constant vibration and temperature fluctuation—conditions that require adhesives with high thermal tolerance and mechanical resilience.

- Building and Construction: Laminated wall systems, exterior panels, and cladding materials benefit from adhesives that can withstand sunlight, heat exposure, and seasonal extremes without degradation.

UNICHEM supports manufacturers across these industries with adhesive technologies designed to meet line integration needs and product performance expectations. Explore industry-specific solutions.

Coil-Applied Adhesives Designed for Performance

Developing the right adhesive solution involves more than chemical formulation; it requires alignment with production systems, environmental conditions, and material compatibility. Adhesives designed for continuous coil application must cure cleanly, bond consistently, and support efficient processing without rework or variation.

Well-formulated systems contribute to:

- Thermal Stability: Resistance to heat-induced failure and structural fatigue

- Mechanical Strength: Reliable bonding across shaped and formed components

- Process Efficiency: Compatibility with high-speed coil lines and curing ovens

- Surface Uniformity: Smooth application and bonding without irregularities

UNICHEM works closely with manufacturers to align adhesive properties with production goals, whether for in-line curing or staged lamination. Our collaborative approach emphasizes technical support, process optimization, and long-term performance in real-world applications.

Delivering Confidence in Every Bond

High-heat-resistant laminating adhesives enable manufacturers to meet the demands of durability, efficiency, and thermal performance in complex product environments. Integrated into coil processing lines, these systems offer consistent adhesion and operational value from production through end use.

UNICHEM offers proven experience in coil-applied adhesive technologies, including single-stage and B-stage curing systems for high-temperature applications. We provide engineered solutions that enhance manufacturing efficiency and long-term product performance. Contact us to learn more about our high-heat-resistant adhesive solutions.